Username: ambrosesmith

Email: ambrose@deakin.edu.au

1. Introduction

The typical McDrive (Figure 1) should be able to handle 120 cars per hour in Europe and 150-160 cars per hour in the US (Marieke 2012). That leaves it no time to suggest alternatives if a product is out of stock. How then does McDonald’s manage its supplies and also select the right places to sell its products?

Figure 1: The McDrive (Source: McDonald’s Corporation)

As I mentioned in my first blog, Iacobbuci (2015) recommends her Marketing Framework where Marketing Management oversees the 5Cs, STP and 4Ps with the aim of enhancing exchange between customers and a firm. The checklist in Figure 2 highlights key areas that a marketer must address in order to device how a product/service will be available in easily accessed places (Place):

- a company’s distribution and logistics channels

- the distribution intensity

- the choice to use push or pull marketing communications

- resolving conflicts among channel entities

Figure 2: Key issues to consider when creating action plan for the third ‘P’, which is Place (Source: Iacobbuci 2015).

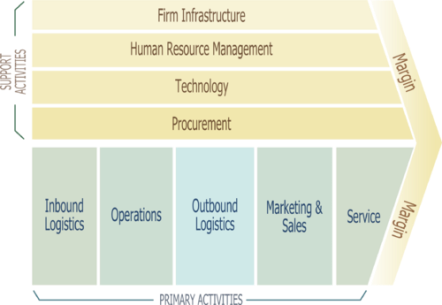

Michael Porter’s value chain (Figure 3) is a different perspective yet completes the picture by showing how logistics and operations activities integrate with others to create value. In order to gain competitive advantage over its rivals, a firm must support the primary and support activities in a unique way that creates greater differentiation (Christopher 2011).

Figure 3: Michael Porter’s value chain (Source: Wikipedia 2016)

This blog attempts to understand McDonald’s distribution channel and supply chain logistics through the use Iacobbuci’s and Porter’s models.

2. Distribution Channel

The most prominent place McDonald’s products can be found are at its restaurants. Other places where the company uses to sell its products are:

- Kiosks

- Postmates website and app

- McDonald’s mobile app

Hence, the company is using the selective distribution channel maintaining a push-and-pull marketing communication (Meyer 2015).

3. Supply Chains

McDonald’s business model is based on the “Three-legged stool” model (Figure 4) created by Ray Kroc (Pfeifferová 2012). In order for McDonald’s to manage its suppliers and franchisees, the Three-legged stool business model ensures that McDonald’s, suppliers and franchisees (represented by one leg of the stool) all work together. Furthermore, the fast food giant implements the 5 Vested Outsourcing rules which is mutually successful to McDonald’s and its suppliers (Kling et al 2012). The rules are:

- Rule 1: Focus on outcomes, not transactions

- Rule 2: Focus on the what, not the how

- Rule 3: Agree on clearly defined & measurable outcomes

- Rule 4: Pricing model/incentives for cost/service trade-offs

- Rule 5: Govern for insight, not oversight

Figure 4: Suppliers, franchiser and franchisee in the three-legged stool model (Source: Fristedt 2012)

4. Inbound Logistics

McDonald’s replaces most of its suppliers through backward vertical integration (Susanto 2012) for the following reasons:

- to reduce cost

- to ensure that its products are of top quality

5. Operations

To speed up the preparation of meals by its unskilled employees, McDonald’s Speede kitchen (Wilson 2006) has:

- a very large grill where one employee can cook lots of burgers simultaneously

- a dressing station where employees add condiments to burgers

- a fryer where one employee can make french fries

- a soda fountain and milkshake machine for desserts and beverages

- counters where customers place and receive their orders.

6. Outbound Logistics

McDonald’s restaurants come in the form of:

- sit-down

- drive-thru

- counter-service

- ski-thru

The ski-thru format is only available in few locations such as a popular Swedish ski resort of Lindvallen, 280 miles north of Stockholm. McDonald’s does not offer home delivery services as yet (Dudovskiy 2016).

7. Conclusion

Through the Iacobbuci and Porter ‘lenses’, the blog was able to determine how McDonald’s implements the third P (Place) of its Marketing Mix.

8. References

Christopher, M., 2011. Logistics & supply chain management, retrieved 14 May 2016, < http://ekool.tktk.ee/pluginfile.php/85964/mod_resource/content/1/062%20Christopher%20-%20Logistics%20and%20Supply%20Chain%20Management%20%282011%29.pdf >.

Dudovskiy, M., 2016. McDonalds value chain analysis, retrieved 14 May 2016 < http://research-methodology.net/mcdonalds-value-chain-analysis >

Iacobucci, D., 2015. Marketing management (MM4), South-Western, Cengage Learning, Mason.

Kling, J., Manrodt, K., Vitasek, K., 2012. Vested for success case study, retrieved 14 May 2016, < www.wipro.com/documents/Vested_for_Success.pdf >.

Marieke, 2012. McDonald’s wants to be assured of delivery, retrieved 14 May 2016 < http://www.supplychainmovement.com/mcdonalds-wants-to-be-assured-of-delivery >.

Meyer, P., 2015. McDonald’s marketing mix (4ps) analysis, retrieved 14 May 2016 < http://panmore.com/mcdonalds-marketing-mix-4ps-analysis >

Pfeifferová, M., 2012. Building a strong brand: a case study of McDonald´s corporation, retrieved 14 May 2016 < http://digilib.k.utb.cz/bitstream/handle/10563/20235/pfeifferov%C3%A1_2012_bp.pdf?sequence=1 >

Susanto, F., 2012. Value Chain and Competitive Advantage of McDonald’s, retrieved 14 May 2016 < https://fagansusanto.wordpress.com/2012/11/22/value-chain-and-competitive-advantage-of-mcdonalds >

Wilson, T., 2006. How fast food works, retrieved 14 May 2016 < http://science.howstuffworks.com/innovation/edible-innovations/fast-food.htm >